PRODUCT产品中心

High aluminum poly light brick mullite light brick

Light heat insulation zone for blast furnace hot blast furnace and soaking pit

Clay, high aluminum, anti carburizing, alumina products

Light heat insulation lining brick for ethylene and hydrogen plant

Light refractory brick with high strength and low heat conduction

General high performance refractory castable

Corundum brick, corundum mullite brick, light corundum brick

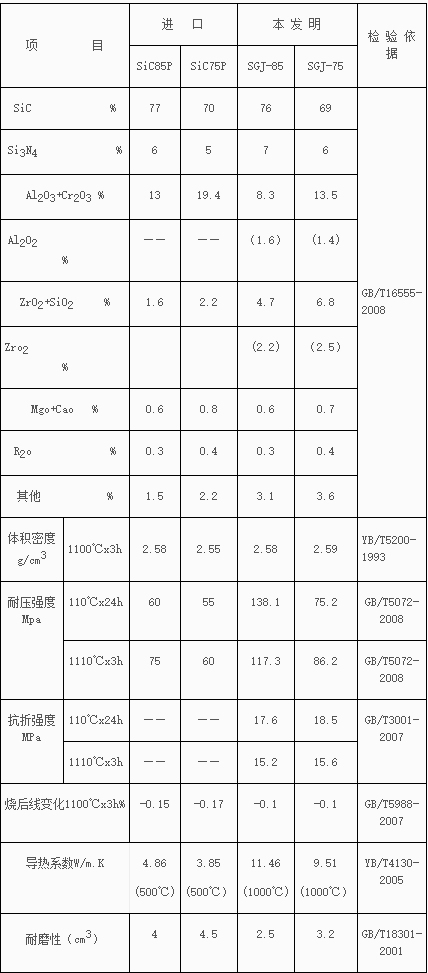

High wear resistant silicon carbide ramming material

-

High wear resistant silicon carbide ramming material

Data download